Foresight MX HUMS for Bell 212 & Bell 412

Download Bell 212/412 Brochure

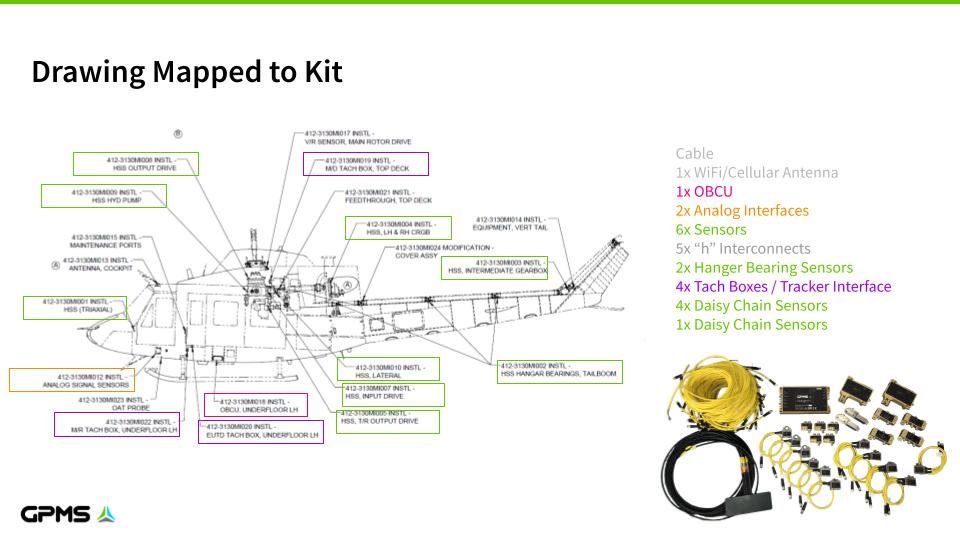

Onboard Kit

Lightweight and rugged, Foresight MX’s onboard kit for the 212/412 is STC certified and acquires vibration data automatically. Processing at the sensor-level delivers exceptional sensitivity and accuracy.

What is Foresight MX & Why Do I Need It?

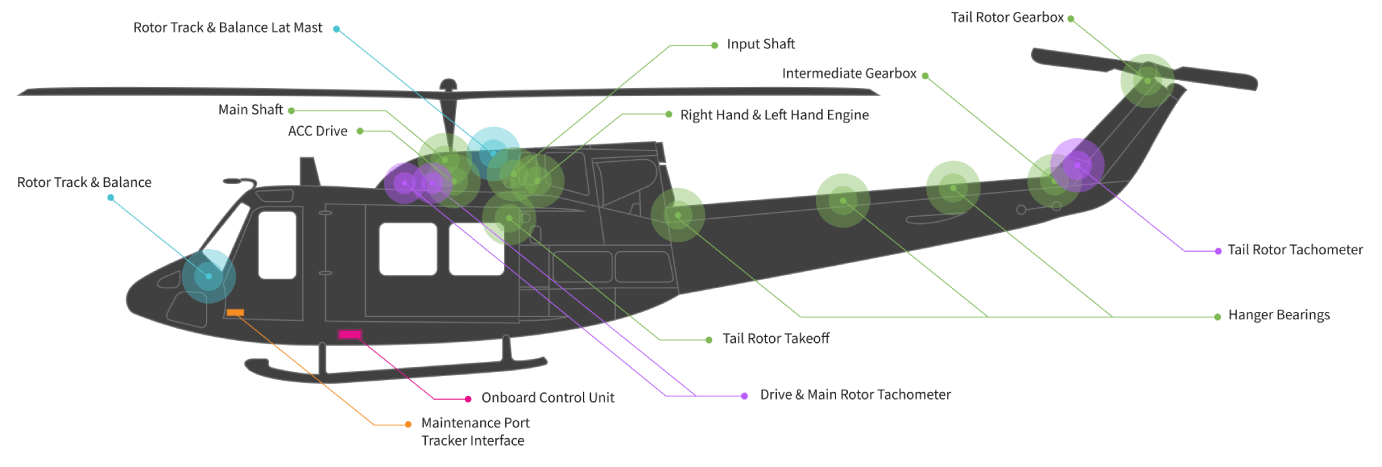

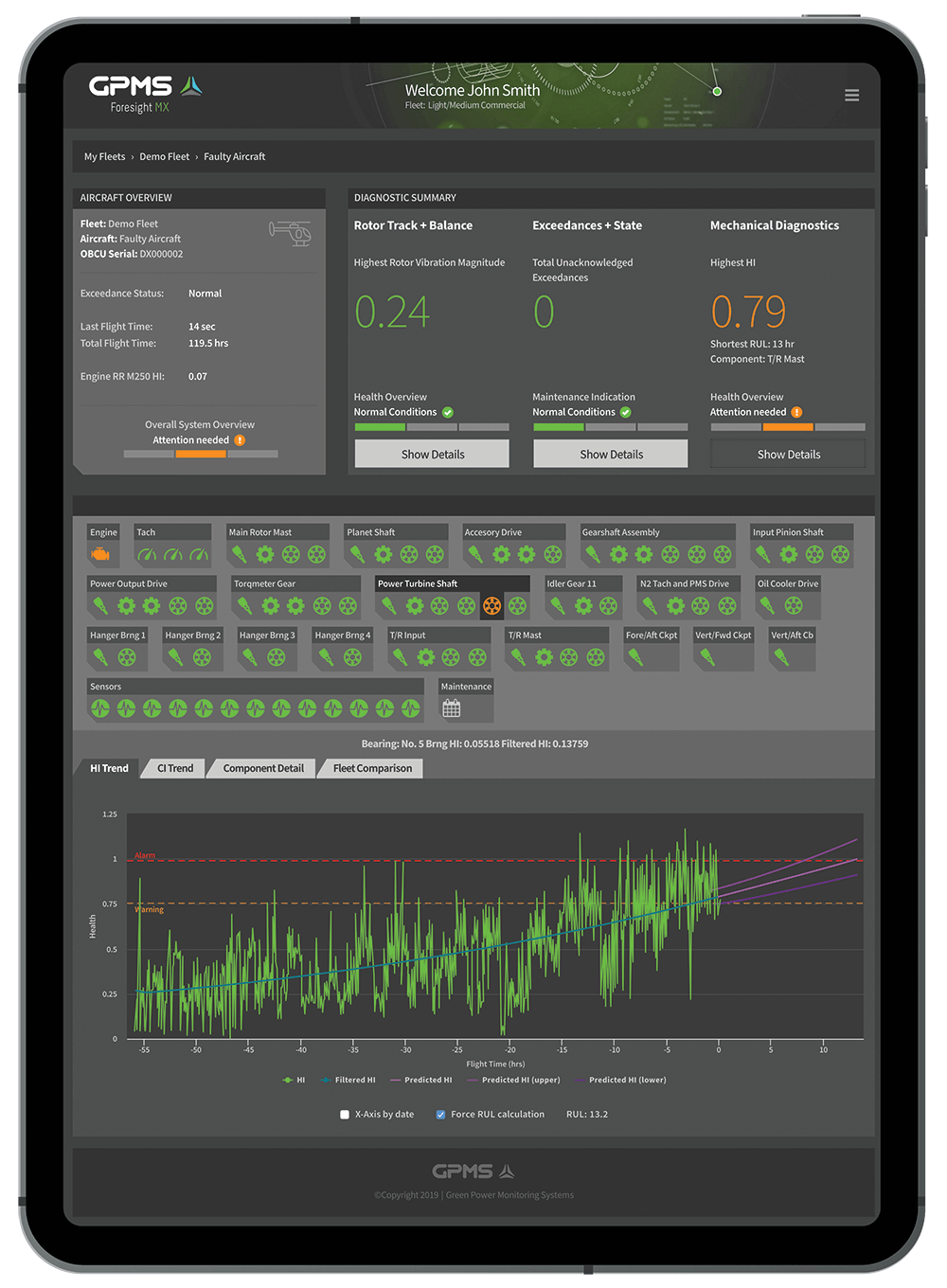

Foresight on the Bell 212 / 412 is a breakthrough tool for rotorcraft operators. Allowing you to continuously monitor your fleet from anywhere, Foresight’s smart sensors uncover when components are starting to wear and our prognostic algorithms display when maintenance may be required. In addition to mechanical & engine health, our advanced health & usage monitoring system provides FDM for your FOQA program, tracks exceedances, and automatically captures RTB data and provides optimized solutions.

Installation Photos

Watch our Foresight MX product video

Features and Specs

CORE FEATURES

Machine Condition Monitoring

- Component vibration monitoring

- Engine performance monitoring

- Prognostic capability providing RUL estimates

- Summary level Health Indicators

- Diagnostic capability via Condition Indicators

Flight Data Monitoring

- Data from avionics via ARINC or analog interface

- Track & graph missions on 37+ parameters; 60+ on download

- Automatic digital capture of OEM exceedances

- Automatic capture operator defined exceedances

- All data exportable into X-Plane for replay

- AC 135-14B HEMS HFDM compliant

Rotor Track & Balance

- Automatic in-flight regime recognition and acquisitions

- Optimized adjustment available post-flight

- Adjustments can be modified, constrained, or overridden

- Complex adjustments (WGTS, PCRS, TABS)

- 1/rev and 2/rev

- No maintenance flights

SYSTEM-WIDE ATTRIBUTES

- Accessibility: Any-device, Anywhere access via cloud+browser

- Interpretability: By maintainer via intuitive dashboards

- Automation: postflight transfer upon cooldown via cellular

- Updatability: HW updates over the air, SW updates in cloud

- Compliance: STC and equivalent civil aviation certifications

- Integrations: Yes via API’S

- Exportability: Yes, via export buttons

- Alerting: Yes, via Email or SMS

- Mixed Fleet Support: Digital or Analog

KIT AND SYSTEM SPECS

- Components: 13 Smart Accelerometers, 3 Tachometers, 1 Blade Track Interface, 1 OnBoard Control Unit (OBCU) with INU/GPS

- Analog Interface: Engine 1 – N1, N2, TOT, Torque

- Analog Interface: Engine 2- N1, N2, TOT, Torque, NR, OAT, Airspeed, PA

- Interfaces: ARINC 429, CAN, RS-485, Ethernet

- OBCU Dimensions: 7.5L x 4W x 1H (inches)

- Mounting Methods: Bolted

- STC Weight & Balance: 7.41 lbs

- Cable and Mountin HW: 7 lbs

- Drivetrain Acquisitions: Up to 1x per minute (configurable)

- Number of Channels: 70+

- Data Processing: Distributed – sensors, OBCU and in cloud

- Connection Architecture: Bused (vs star) to save weight

- Power Draw / Voltage: ~0.65 amps @ 24v 18 – 35 Volt Range

- Operating Temperature: Sensors -40 – 105C; OBCU -40 – 85C

- Data Storage: 16GB, USB Memory flash storage

- Self Monitoring: Yes, via sensor dashboard

- Installation Time: ~120 hours

- Modem: WiFi, Cellular via integrated modem

- Hosting: AWS IoT Cloud, Optional Dedicated Ground Station

- Security: One way connection, multipoint authentication